Manufacturing Unit

Read MoreAbout Engineering

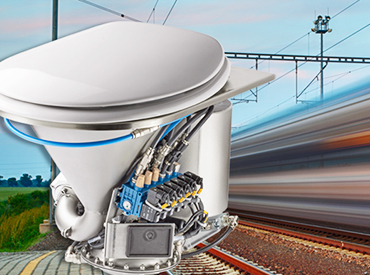

Identifying new-age engineering needs of organisations across the board, Spectron formed the engineering division in 2000. The division facilitates a range of activities from procurement of raw materials to processing them for final installation. These processes are designed to suit the requirements of pharmaceuticals, petrochemicals, consumables and FMCG industries. It’s powered to offer services like fabrication, erection, welding and testing that parallels international efficiency standards.

The manufacturing facility is approved under the ASME U, R & AB stamping.

Our projects involve shut down and start-up jobs and lump sum turnkey (LSTK) projects. LSTK projects of quarterly, half-yearly and annual duration are a major component of this division's success.